Presented by Simon "The Diamond" D'Vali

The UK's foremost authority on collectable cues

Exclusive interview with Custom Cue maker Wayne Holmes

Wayne Holmes…Custom Cue Maker

Wayne Holmes has been making custom cues for many years. He has a reputation for extremely high quality work and the playability of the finished product is up there with the best cues available. I have been ordering cues from Wayne for a number of years now and his profile has recently shot through the roof on the announcement that he will be taking a well earned break after this current batch of cues. Wayne very kindly took time out to do this interview for all the folk at Pro9……

Click on "Read More..." for the details.

Wayne, good day to you sir from all at Pro9.

Good evening Simon and all the Members at Pro9. This is very flattering. Thanks for inviting me.

How long have you been making cues?

I made a few before I went into the Military in 1966, but I gave them away. I felt I could do higher quality work. In 1971, after my military service, I started a small business doing cue repairs to help pay my college expenses. At the same time I was refreshing my woodworking skills and saving whatever money I could to buy equipment and machinery. I finally made my first cue for sale in late 1971. It sold for $45.00.

How many cues do you make a year and is the demand getting greater?

I plan on making only 40 to 50 cues in 2006. I have made as many as 175 in one year, but in a one-man shop quality suffers with that quantity. Yes, the demand has really increased, especially over the last five years.

Your Father, Orie Holmes was a legendary cue maker before you. How much did you learn from your father and was cue making a natural path for you to follow?

Dad was undoubtedly the most demanding person I’ve ever worked for, or with in my entire life, but he was also the kindest and most knowledgeable man I have ever known. He had an uncanny knowledge of woodworking, almost a sixth sense you might say. Not only would he show me how to work with wood, but he would also show me why he did things a certain way. At that time, some of it made sense, some of it didn’t. Today, it’s all crystal clear to me. Obviously some of the technology used in making cues has changed since then, but there are still several of his techniques I use today. I feel sure Dad would approve of my work if he were still with us. He passed in 1996. Naturally I do miss him.

I suppose making pool cues was my natural path, but it wasn’t until the early 1960s that I realized it. I was drafted into the US Army in 1966 and had to put things on hold for a few years, but I never lost sight of my goal. I still have a few goals I intend to reach before retiring.

What do you do when you are not making cues?

That’s an easy question…I get my “Honey Do” list done

You have been in the business for many years. There was no internet when you started so advice would have been pretty thin in those days, what is the most important piece of advice you could give an up and coming cue maker of today?

I don’t believe there’s a short answer to that, Simon. There are three keywords that come to mind though. Education, determination, and patience! First learn absolutely everything you can about the trade before venturing into it. If you can find a senior cue maker that is willing to extend an apprenticeship to you, by all means accept it. I was fortunate…I was taught by one of the best! Seek out advice from professionals on how to start a business and develop a business plan. S.C.O.R.E., which is Service Corp of Retired Executives, would be a good organization to contact.

Above all, be patient! Success is not reached quickly in this trade, if it’s ever reached at all. I see so many talented young people starting into this business, only to become frustrated when they find that overnight success is not guaranteed. A new cue maker is destined to eat a lot of beans before he can afford hamburgers.

If it hadn’t been cue making, what do you think you would have done for a profession or job?

Actually I had another career field as well. I was Superintendent for a commercial construction company for many years. I retired from that in 1996. If it weren’t for the income that provided in the 70s and 80s, I doubt I would have reached many of my goals in cue making.

I hear you have a serious game on the green baize, how important is it for a cue maker to be able to shoot a good stick in order to make a good stick?

I think it’s very important! Think of it this way. Can a Janitor do a proper job of cleaning a floor if he doesn’t know how his mop or broom performs? Or a Professional Chef, can he prepare a special dish if he doesn’t know how that food is supposed to taste? Likewise, if the cue maker doesn’t understand the intricacy of the game, he cannot possibly understand how a cue should perform. Not knowing how a cue should perform, how can he possibly make one that works well?

Yes, that makes perfect sense. Players in the UK are now coming round to the advantages of custom cue work. I see more and more players ordering custom cues. Also there are a growing number of players in the UK using a Wayne Holmes. For a player, ordering a cue to their specifications for the first time is a daunting task. I can’t convey how easy it is to order a cue from yourself, can you help me out???

I agree. UK players are not only becoming aware of the advantages, but also the fact that custom cues are usually a better investment than production cues.

I know the process of ordering a custom cue can be an uncomfortable one to deal with. For me it seems an easy process, but then, I do it every single day. I try to make the process easier by first putting myself in the place of the client. I want it to be a joint effort, not simply a purchase. It isn’t unusual for me to invite a client to the shop to select their wood, talk about designs, or play a game or two to make note of his playing style. One particular client even did some of the turning on one of his cues. I’m currently working on the 5th cue I will have made for him. Anything can be fun if you make it so. It’s just a matter of finding the excitement in whatever it is you’re doing.

Below this interview, I have described some cues you have made. In the text, I have used the word ‘recut’. Could you explain what a recut is in a cue?

I’ll try. If the Members will take a look at your Ebony & Tulipwood cue, they will notice the Ebony points appear to have a Tulipwood veneer surrounding them. This was done by first installing Tulipwood points into the Ebony forearm. Once the Tulipwood points were installed, the forearm was mounted onto my milling machine again, and a “V” groove was “recut” into the Tulipwood. An Ebony point was then installed into that “V” groove. The assembly was then turned smooth and round and was then made ready to be joined to a handle. The process is similar to installing veneered points, only in that the point material is installed into a "V” groove that is cut into the forearm. When done properly, recut points are always more even in length than veneered points. They are definitely stronger, and in my opinion absolutely beautiful! I will be launching a new page on my web site on May 7th that will show the process in more detail. If anyone is interested, please feel free to visit.

Wayne, thank you for taking time out to do this interview. Our regards to your lovely wife Pat and don’t forget……I want the 7 and the breaks when I hit your shores!

Thank you for inviting me Simon. Pat sends her very best. She also suggests that if I give you the 7 and the breaks, that the winner buys the lobster dinners

Sounds good to me!! Too much home advantage with your Brunswick though! I may need the 6, he, he! SDV

For more information on Wayne’s Custom Cues, check out his website, www.waynecustomcues.com

Or contact Wayne via email on wayne@waynecustomcues.com

List of other satisfied users in the UK (not exhaustive):

Matt Gleaves

Philip Burford

Stefan Fisher

Lee Rigby

Sam Carder

A few examples of Waynes cues…..

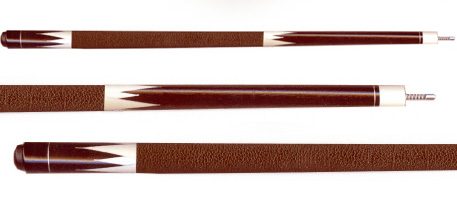

Wayne Holmes Cues pic1

The brown cue (owned by Lee Rigby….Riggers) is made from curly Hawian koa wood (Wayne Holmes Cues pic1 + 2). It has an ivory joint with a radial pin, ivory butt cap and solid ivory ringwork bounded by sterling silver. The wrap is black leather. The weight is 19oz and Wayne made 2 custom Predator 314s for this cue.

Wayne Holmes Cues pic2

The first black cue is one of my own (Wayne Holmes Cues pic1 + 2). It has 8 ebony points recut with tulipwood into an ebony forearm. Ivory joint with a radial pin and an ivory butt cap. The ringwork is solid tulipwood bounded by sterling silver and the wrap is black leather. Wayne made 2 custom 314s for this cue also.

The last 2 ebony cues belong to Matt Gleaves and UK junior champion Philip Burford. I will let Matt and Phil explain their specs of his cues when you run into them at an event.

Wayne Holmes Cues pic3

The next picture shows the beauty of the curly koa wood on Rigger’s own cue with the matching 314s (Wayne Holmes Cues pic3).

What the customers will all say is that the hit and balance of these cues are better than anything they have ever used before.

Wayne Holmes Cues pic4

Many years ago, when I ordered my first Wayne, I qualified at the next event I went to….for the first time and with the new Wayne I just received! This is the cue shown below (Wayne Holmes Cues pic4). It is all ebony and ivory with a leather wrap. The 16 ivory points are veneered with sterling silver. An absolutely pain staking process Wayne went through. Cutting the short ivory points was no easy task either.

Wayne Holmes Cues pic5

The last picture (Wayne Holmes Cues pic5) shows the super cue next to a beautiful ebony and amboyna handled Wayne commissioned by Matt Gleaves.

If you decide to order a Wayne cue, you can be assured of the highest quality finished product. Only the best materials are used and 100% is given to every commission. Don’t take my word for it, check them out for yourselves.